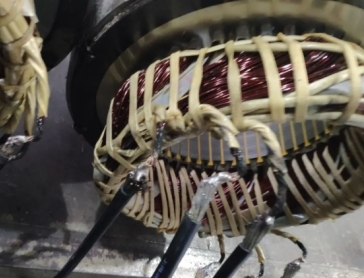

Ngoku,isigaba sesithathu soveliso ac motoriingcingo ezikhokelayo zimela into ebalulekileyo yolungiselelo lombane kwimveliso yemoto, equka imimandla yokufakwa kombane kunye nemiba yokuqhuba. Ngokwethiyori, ngaphandle kokuba ukhetho kunye nokufakelwa koxinaniso lwangoku luhambelana nemimiselo efanelekileyo, inxalenye yocingo olukhokelayo aluyi kubonisa nayiphi na imiba enxulumene nobushushu. Nangona kunjalo, ekusebenzeni, iimeko zolu hlobo lwengxaki zenzeke, kwaye ukuze ufumane ukuqonda okunzulu kwezizathu ezisisiseko, kuyimfuneko ukuhlolisisa iimpawu ezithile zokungaphumeleli kumbuzo.

(A). Zonke iingcingo zokukhokela zibonisa iimpawu zemiba enxulumene nokufudumeza. Ekujonganeni nalo mbandela, ingqwalasela yethu kukuthotyelwa kobubanzi kunye nokubunjwa kwezinto eziphathekayo zomqhubi wocingo olukhokelayo. Xa kuvela lo mba, kusenokwenzeka ukuba ayingomcimbi nje weempazamo zofakelo lomntu ngamnye, kodwa yingxaki yenkqubo echaphazela iiyunithi ezininzi. Olu hlobo lwengxaki lunokubalelwa kumgangatho wenkqubo yokwenziwa kweemoto.

(B). Iingxaki zokufudumeza ucingo olukhokelayo. Le ngxaki yinto eqhelekileyo yempazamo eye yaxelwa ngexesha lokusebenza kweinjini yokwazisa. Kwiimeko ezininzi, le mpazamo ikwakhatshwa nengxaki yokukhutshwa kwebhodi ye-terminal. Uhlalutyo lwamatyala okwenene lubonisa ukuba le ngxaki ibangelwa uxhulumaniso olubi lwendawo yocingo olukhokelayo. Inokuthi yenzeke kwindawo yoqhagamshelo phakathi komgca ongundoqo ojikajikayo wemoto kunye nocingo olukhokelayo, kwaye ibonwa ngokufuthi ekulungiseni ucingo olukhokelela kwimoto kunye netheminali, okanye ikhonkco lokulungisa phakathi kwetheminali kunye nebhodi yetheminali.

(C). Isiganeko sokufudumeza esiqatshelweyo sinokubangelwa ukusebenza kwe-voltage ephantsi. Lo mbandela ufana nesiganeko sokufudumeza okujikelezayo. Xa i-motor isebenza kwi-voltage ephantsi kwixesha elide, i-current iya kwanda kakhulu. Ngokufanelekileyo, ucingo olukhokelayo kufuneka lukwazi ukumelana nomsinga omkhulu. Ngokukodwa, xa i-diameter ye-lead wire ingekho mkhulu ngokwaneleyo, ukuxinana okuphezulu kwangoku kuya kubangela ukuba ucingo olukhokelayo lube shushu.

(D) Umba wokufudumeza kwinxeba iingcingo zokukhokela. Lo mbandela uyingqayizivele kwiinjini ze-rotor zenxeba. Isizathu esisisiseko sesiganeko sokufudumeza sinokuthi sibangelwa yizinto ezahlukeneyo, kubandakanywa i-welding yocingo olukhokelayo, ukudityaniswa kwendandatho yomqokeleli, ukuhambelana komqokeleli kunye ne-carbon brush, kunye nempahla ye-carbon brush ngokwayo. Ngaphaya koko, ngumba onzima ngakumbi. Kulolu hlobo lwemoto, ukukhupha umoya kunye nokutshatyalaliswa kobushushu bomqokeleli wendandatho kubaluleke kakhulu. Ubushushu bemigangatho emithathu yeringi ye-ainqanaba lesithathu motorumqokeleli ring iyahluka kakhulu, nto leyo echaphazela ubushushu rotor lead. Nangona kunjalo, inqanaba lempembelelo liyahluka ukusuka kwinjini ukuya kwenye.

(E) Isixhobo kunye nokucocwa kwetheminali kufuneka kwakhona kuthathelwe ingqalelo. Ukongeza kwindima yabo ekukhuseleni iingcingo ezikhokelayo kunye nebhodi ye-terminal, iitheminali zokukhokela iimoto kufuneka nazo zibonise ukuhanjiswa kombane okulungileyo. Ukuba i-terminal material inomgangatho ophantsi, ngaphezu kokukwazi ukuphuka ngexesha lofakelo, umcimbi obaluleke ngakumbi kukuba ukuchasana koqhagamshelwano lwecandelo lokudibanisa kuya kwanda, okukhokelela ekuphakameni kwamaqondo okushisa kwintambo ekhokelayo. Ngaphaya koko, ipeyinti eshiyekileyo kwitheminali, enokuthi ibe nesiphumo sokuba ucingo olukhokelayo lufakwe kwipeyinti kunye nokujikajika, lunokubangela ukuba ukuchasana kwendawo kube kukhulu kakhulu, oko kukhokelela kwingxaki yokufudumeza kucingo olukhokelayo.

(F). Ubume bebhloko ye-terminal alunangqiqo. Ukuba isakhiwo se-terminal block sithathwa njengento engafanelekanga, kunokwenzeka ukuba iindawo zokudibanisa ziya kukhululeka ngexesha lokusebenza kwe-motor, enokuthi ibangele iingcingo ezihamba phambili kunye ne-winding overheating.

Ngokubhekiselele kolu hlalutyo lukhankanywe ngasentla, kunyanzelekile ukuba kuqinisekiswe ukuthembeka kokusebenza kweemveliso zemoto ngokuphumeza ukhetho oluqinileyo, ukulungiswa, kunye nenkqubo yokulondoloza iingcingo ezihamba phambili. Le ndlela ibalulekile ukuthintela umonakalo onokwenzeka wemoto yonke ngenxa yokusilela kwendawo.

Ixesha lokuposa: Oct-30-2024